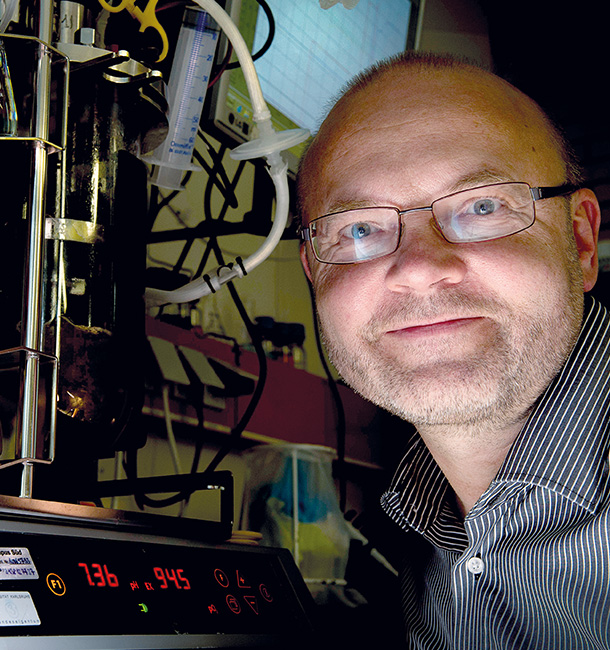

Prof. Christoph Syldatk wants to use innovative biotechnology to make biomass more profitable as an alternative to petroleum. In doing so, he is specifically focusing on the use of raw materials that do not compete with food or animal feed.

It is not without good reason that crude oil is called "black gold". The fossil raw material is the world's most important energy supplier and, when processed into plastics, forms the basis of countless everyday objects. However, as economical as its use may be, the dangers for the environment are equally high, during extraction and during industrial utilization. In addition, oil reserves are dwindling and demand is constantly rising. Being aware of this background, the use of biomass, which can replace crude oil as an energy source and also as an industrial feedstock, is becoming increasingly important.

In Germany, mainly starchy plants such as corn or sugar beets, but also cereal proteins or vegetable oils, are used as biomass at the moment. However, as demand increases, competition for use between the energy sector and the food and feed industries is unavoidable. "At Institute of Process Engineering in Life Sciences, we are therefore focusing on processes that facilitate the use of so-called second-generation biobased raw materials – raw materials that do not compete with food," explains Prof. Christoph Syldatk. As head of the Sub-Institute for Technical Biology, makong a contribution to sustainable energy and raw material supply with the help of state-of-the-art biotechnologies is important to him.

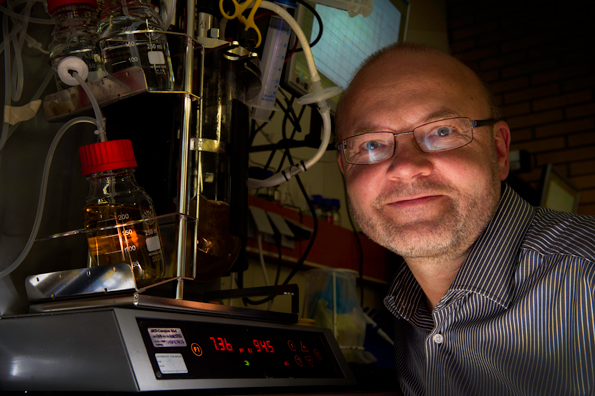

Lignocellulose is a raw material that has hardly been used to date for the production of basic and fine chemicals. It is available in large quantities and, due to its low cost, can also be a good economic alternative to fossil raw materials. The polymer is the main component of the cell walls of lignified plants and can be obtained as a substrate from residues and waste from agriculture and forestry, for example from straw, green waste or sawdust. It contains sugar building blocks that are suitable as a substrate for the cultivation of microorganisms, e.g. for the production of biosurfactants or bioethanol, which in turn can form the basis for the chemical production of many downstream products and bio-based plastics. However, in order to use lignocellulose as a raw material, it first must be separated into its individual components, known as fractions – a step that is currently still time-consuming and associated with high costs. As a result, there are currently only a few chemical products made from lignocellulose. Only bioethanol is already being produced in larger quantities in pilot plants.

"For the establishment of the raw material, a reduction in production costs is essential. That is why our research group is working on the question of whether it is possible to produce novel biosurfactants by microbial or enzymatic synthesis, starting from lignocellulose fractions. These could then be used, for example, as emulsifiers in the cosmetics or pharmaceutical industries," says Prof. Syldatk.

"The goal is to establish a sustainable and environmentally friendly alternative to petroleum. Therefore, innovative technologies must be developed that make the use of biomass attractive from an economic point of view as well."

In addition, research is being conducted at the Institute of Process Engineering in Life Sciences on further process optimization, for example, on the use of microorganisms in the utilization of synthesis gases produced from straw in the KIT bioliq® plant or on the microbial production of dicarboxylic acids as plastic precursors. Prof. Syldatk attaches great importance to leaving a green footprint. He also wants to pass this on to future generations of young scientists. For example, he covers the topic of "Biotechnological processes in a future bioeconomy" in courses.

Prof. Ralf Kindervater, honorary professor of KIT and managing director of BIOPRO GmbH, the state company in Baden-Wuerttemberg for the topics bioeconomy and biotechnology, pharmaceutical industry and medical technology, is a lecturer at the Institute of Process Engineering in Life Sciences. Together with Ph D. Detlef Schmiedl from the Fraunhofer Institute for Chemical Technology (Fraunhofer ITC) and Prof. Syldatk, he holds a lecture on "Bioplastics." In addition, Kindervater is organizing a lecture on "Commercial Biotechnology" together with other colleagues from KIT and the private sector. Kindervater comments: "I very much welcome the fact that we can work hand in hand here and impart both, ecologic and economic knowledge. It is important for us that the students learn when biotechnological processes are suitable at all and when chemical processes make more sense."

Not only are students interested in the topic of bioeconomy, but there is also great demand from industry. "Many suppliers are already waiting in the wings. But as long as the use of fossil raw materials is much more profitable financially, it will take time for biomass to replace 'black gold'," Kindervater and Syldatk explain. "That's why it is so important for us to use innovative processes to show how costs can be reduced to kick-start a functioning bioeconomy."