Transporting electricity without loss – superconductors make it possible. With a new manufacturing process, KIT scientists want to pave the way for mass production of the technology.

The energy turnaround requires the expansion of the German power grid by more than 5,000 kilometers. It is the only way the required energy, which is largely generated in the north of Germany with the help of renewable energy sources such as wind power, can be transported to the south. However, the idea of large overhead power lines near one's own home often triggers rather resentment among the population.

Although it is possible to transport the electricity underground, the special underground cables are associated with high costs and high space requirements for the routes. KIT is conducting research on a much more efficient and powerful alternative, with which new power lines can be built much narrower: superconductors.

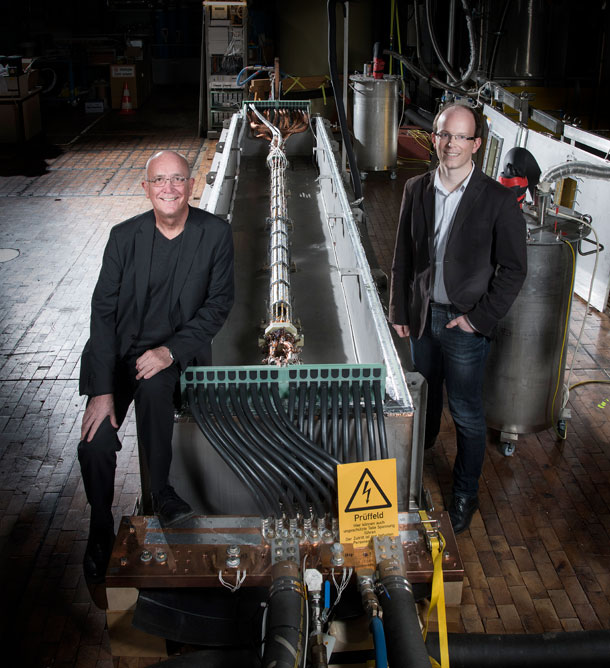

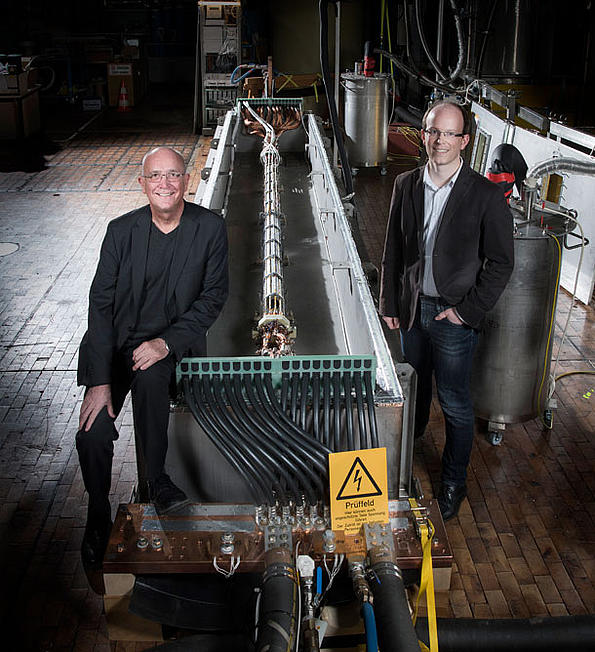

"We are not doing research to be able to call ourselves inventors, but to see the technology in use one day."

Ph. D. Walter Fietz and Ph. D. Michael Wolf are research associates at the Institute of Technical Physics (ITEP) and are familiar with the advantages of the technology: "Superconductors enable almost loss-free transport of direct current at extremely low temperatures. However, handling requires a great amount of know-how, which makes industrial application difficult."

Superconductors were discovered in 1911 and for a long time it was assumed that they only work below 30 Kelvin (-243°C), which required cooling with helium. A revolution came in 1987 with the discovery of high-temperature superconductors (HTS), which exhibit superconducting properties as low as 77 Kelvin (-196°C) – a much more energy-efficient and thus cheaper solution, since HTS cables can be cooled with liquid nitrogen.

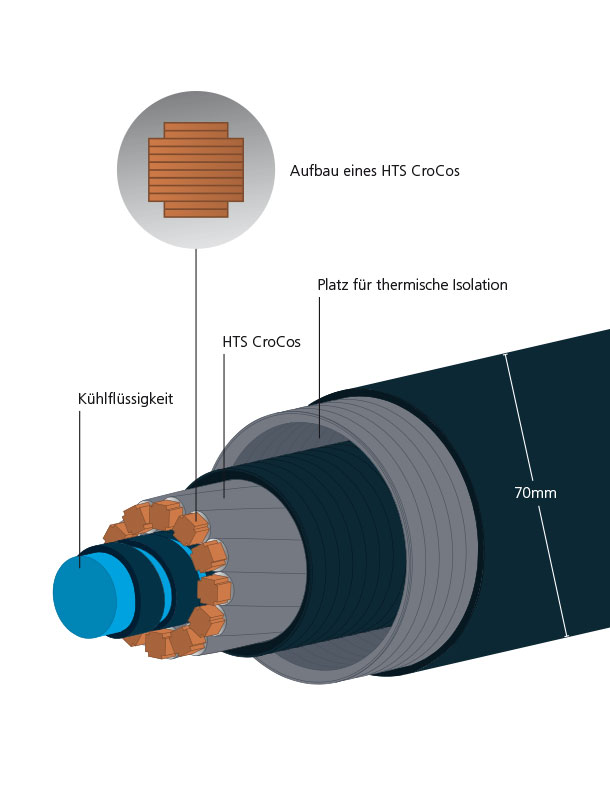

"The basis of such conductors is formed by thin metal tapes coated with a layer of superconducting yttrium-barium-copper oxide just two micrometers thick. In order to be able to use these tapes on a large scale, we addressed the question of how to bundle them in the best possible way," says Fietz. The result is a new conductor design in which four-millimeter wide strips are stacked on the outside and six-millimeter wide strips in the middle.

If you look at the conductor in cross-section, you can see the cross shape of the HTS CrossConductor, HTS CroCo for short, which gives it its name. For production, a process designed for industrial production and long lengths was developed at KIT, in which the HTS tapes can be ordered in one step, soldered into a cross, twisted if desired and filled with solder to a circular cross section. "We currently manufacture at a rate of about 30 centimeters per minute, but that can certainly be increased if needed," Wolf explains. The width of the HTS tapes can be varied as needed. An HTS CroCo consisting of four- and six-millimeter-wide tapes has a diameter of just 9.7 millimeters and can transport about 3,100 amps without loss at 77 Kelvin. However, other geometries have also already been manufactured and tested on a laboratory scale.

HTS CroCos can serve as the basic unit for high-current cables by combining several of them. In a demonstrator built at KIT in 2018, they tested a prototype of a cable that consisted of 12 HTS CroCos. This cable carried 35,000 amps – an enormously high current compared to a normal overhead DC cable with about 2,000 amps per core or a standard household outlet with only 16 amps.

"Now we want to take our research into application. To do so, we are working with Vision Electric Super Conductors as an industrial partner. The company is a system integrator for turnkey superconducting systems and has licensed our technology, Fietz says. "HTS CroCo can be used in diverse industrial applications – from connecting solar farms to coils for generating large magnetic fields to power supply on ships or high-current lines in futuristic all-electric airplanes," Fietz says. He ads: "Our next important milestone is to demonstrate that CroCos can be manufactured in long lengths and wound directly onto a cable drum."