How Heike Schuchmann and Marc Schlender want to reduce investment and operating costs in the milk processing industry.

They call it the "Milky Way of the World." The Al-Safi dairy farm is located 100 kilometers southeast of the Saudi capital Riyadh, in the middle of the desert. By far the largest dairy in the world, it is home to around 50,000 dairy cows. Every day, 800,000 liters of milk are produced for the Asian market there. In Germany, comparatively, 12,000,000 liters of milk are sold per year. The energy input of the dairy farm is enormous and hardly imaginable. Not only animal husbandry involves high energy costs, but also the processing of raw milk into safe and stable drinking milk involves extremely high energy consumption.

For more than ten years, Professor Schuchmann from KIT and her team from the field of food process engineering have been researching a way to significantly reduce the energy consumption of an important and energetically very expensive sub-step, the homogenization of milk. In this process, milk fat globules are broken down to sizes around 300 to 700 nanometers. Every drinking milk product known to us and almost all downstream milk products pass through this processing step. However, homogenization is not only limited to food processing. Dispersions and emulsions such as creams, paints, varnishes and medicines are also produced using this conventional process. Homogenization can improve product properties such as color, consistency or taste. In particular, however, it improves long-term stability so that the product can be further processed or marketed altogether.

Professor Schuchmann's research initially focused on the dairy mass market. The milk industry is significant for the use of high-pressure homogenizers. In a research project, KIT scientists developed an innovative process that can produce milk and dairy products with up to 90 percent less energy. The solution proposed by the KIT team lies in a novel microstructured process plant for high-pressure homogenization. The initial equipment was developed in cooperation with the KIT Institute for Microprocess Engineering. "We considered how to optimize the homogenization process while saving energy, and first took a close look at the way milk is produced: Where exactly do we use so much energy? And why?" explains Schuchmann.

"What drives me is the possibility of altering product structures on a physical basis. I am firmly convinced that a lot of additives in products could be dispensed with by means of physical process optimization. And if a lot of energy is saved along the way, that makes me more than satisfied."

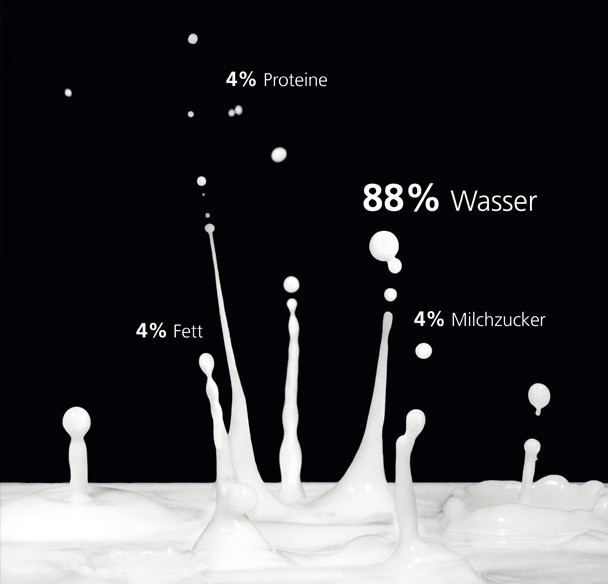

Milk consists of 88 percent water and about four percent of proteins, lactose and fat respectively. The standard procedure is to deliver the freshly milked raw milk to the dairy. There, the milk is heated and split into high-fat cream and low-fat skim milk in a separator. The two substances are then mixed back to the target fat content, for example 3.5 percent. Re-mixing of the milk typically takes place before the homogenization step begins. The product, which now again contains proteins, lactose and, above all, the high proportion of water, is channeled through a valve at 200 to 250 bar during homogenization with the aim of distributing the fat droplets more finely and evenly. However, it quickly became clear to the scientists that the amount of energy required in this process step is hardly sustainable, especially since most of the product does not require this energy input at all. So how can we get around the completely unnecessary water compaction? Simply omit it?

To solve the problem, KIT food process engineers developed SHM technology. SHM stands for Simultaneous Homogenization and Mixing. The innovative technology takes advantage of the standard built-in separation step. Instead of adding the water again before the energetically costly step, as is usually the case, this water-containing skim milk is not added again until directly after it has been shot through the valve. "The idea was to send only the cream through the valve at high pressure, but not the skim milk. However, we use the skim milk to stabilize the new, small fat globules in the cream. For this purpose, we developed a special pinhole orifice plate, also called SHM orifice plate. This is an orifice plate with a downstream micromixer that prevents fat globules from sticking together. No one had been able to solve this problem before us. The skimmed milk can then even be used to cool down the milk again quickly, as it is very hot when pressed through the mixer,” explains food technologist Schuchmann. "This preserves proteins and enables fat globules to be broken down even more efficiently." Tested on a laboratory scale, it turned out that the volume of the stream to be homogenized can be reduced by up to 90 percent. "The use of our newly developed pinholes offers considerable advantages over conventional high-pressure homogenizers with flat nozzles," says doctoral student Marc Schlender, who filmed the milk shooting through the pinholes with a high-speed camera. This way, ingredients such as cocoa or sugar can also be added to the skim milk. These flavor-bringing particles no longer have to be forced through the valves under high pressure. While the ingredients taste delicious, they are highly abrasive and destroy process equipment within a few hundred hours of operation. "Our new SHM valve not only saves process energy, but also protects the equipment and reduces the cost of maintenance and cleaning," emphasizes Schlender, adding, "With our new technology, significantly reduced pumping capacities are required, which is of particular interest for capacity expansions of existing plants or new investments."

What worked well in the laboratory showed problems when scaled up: the prototype of the simultaneous homogenizing and mixing orifice developed by the scientists did not achieve the required mixing efficiency at pilot scale. The KIT scientists were able to show that this was not technically feasible at the extremely small dimensions. They therefore transferred the idea to the type of valve that is currently used industrially in large-scale plants. The industrial scale now allows sufficient flow rates for the desired mixing effect. The SHM flat valve was built in cooperation with plant engineers at KIT.

An industrial trial run took place in summer 2013 at the Naarmann private dairy. An effort that turned out to be very low for the dairy. Schlender brought and installed the SHM valve and the test run was carried out immediately under the supervision of the KIT scientist. It worked right away. "For us, it was important that the SHM valve developed at KIT could be integrated into our existing plant geometry and that no new machines were required. The energy-saving result is impressive. It is also of great interest for our medium-sized company that we can increase capacity up to eightfold with our existing equipment without a high investment," says Claus Naarmann, Managing Director of Naarmann GmbH.

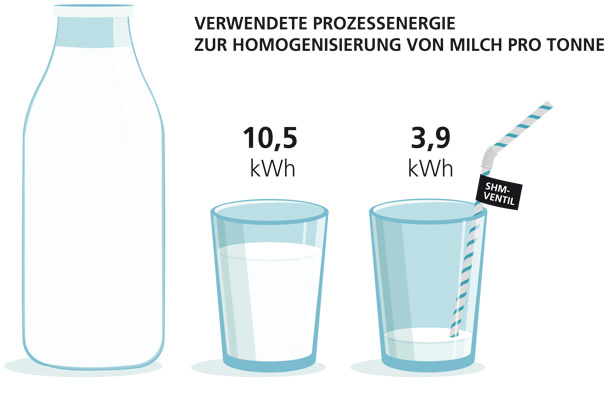

This industrial trial confirmed the high energy-savings potential predicted by the scientists. The process energy required to homogenize milk was reduced from 10.5 kilowatt hours per ton of product to 3.9 kilowatt hours per ton, which is roughly equivalent to the power consumption of two washing machines in washing mode. With the new SHM valve, the product was even improved. "The SHM geometry still needs improvement by far, but for a first demonstrator it worked very well," Schlender says.

In the meantime, the research institute has already developed new types of valves and found many new applications. An industrial-scale pilot plant is also under discussion with an industrial partner. "With our research, we would like to contribute to the competitiveness of the food industry, a sector dominated by SMEs, and we are trying to increasingly place our technology in companies," says Professor Schuchmann. "Saving energy by changing process control also has an impact on the product. We want to think and research across industries to specifically adapt our components to each product requirement. These are our goals for the coming years." The scientists have already been able to prove in practical tests that SHM technology has great application potential in industry. Now the task is to convince the broad industry of the enormous cost savings and quality improvements.