How Prof. Mehdi Tahoori wants to enable new functions for smart products using printed electronics.

Is the milk still fresh?

A milk carton with a freshness sensor that shows retailers and consumers the degree of freshness. A temperature sensor on the wine bottle that checks the optimum drinking temperature. A plaster that notifies the person being treated when the wound has healed sufficiently. These are possible examples of smart products of the future. "At first glance, many think that no one needs this. On the other hand, 20 years ago we also didn't have the vision that smartphones would become indispensable and that you could get the multiple functions on such a small device. In the beginning, you could use it to make a phone call and take a picture, but now we do all kinds of things with it, so it's hard to imagine our everyday life without smartphones," says Prof. Dr. Mehdi Tahoori, Chair of Reliable Nano-Computing (CDNC) at the KIT Institute of Computer Engineering (ITEC).

Printing the smart products of tomorrow?

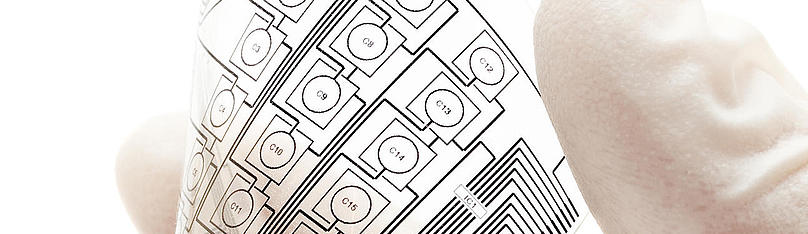

Together with KIT's Institute of Nanotechnology (INT) and several international universities, Tahoori has set himself the task of disseminating fast, inexpensive, and reliable (mini-)computers for the above-mentioned application scenarios. "These smart products need mini-sensors that can store a lot of data and read it out reliably," Tahoori explains. Mini-processors or chips used today in electronic devices such as smartphones or smartwatches are based on silicon technologies. These consist of a very large number of components and transistors, which makes them very complex systems. "For the very low-cost products we are thinking of, silicon technology is reaching its limits. It requires very complex manufacturing processes that are enormously costly. Even the smallest silicon chips, for example Java Cards or RFID tags, are too expensive to manufacture for what we are trying to do. When we think of products such as an intelligent band-aid or a milk carton with a freshness sensor, we have to offer the electronic components at very low cost so that the end product does not become more expensive as a result. This is simply not possible with silicon technology," says Prof. Tahoori.

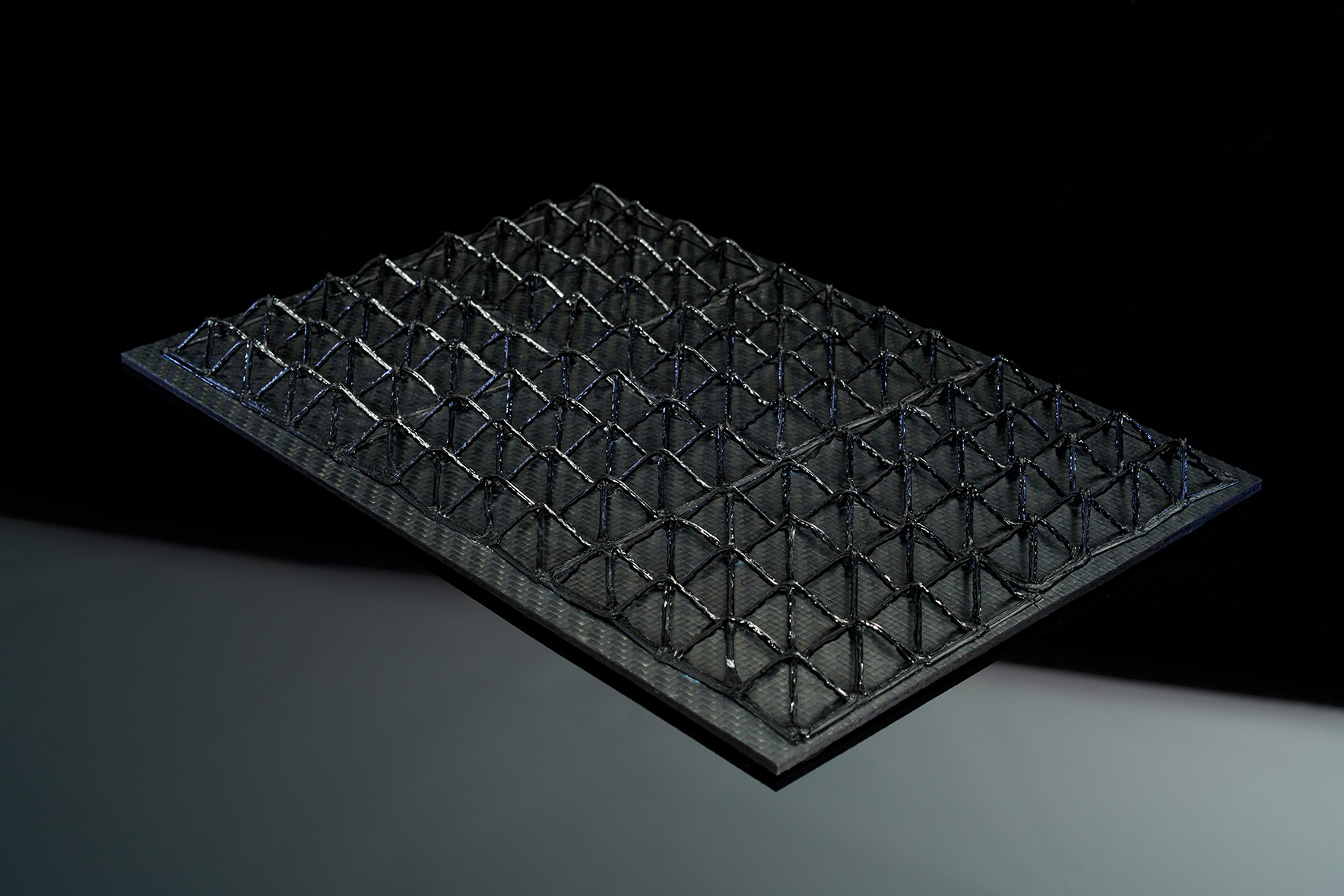

Within the PRICOM (printed computing) project, Tahoori and his team are therefore focusing on developing new computer architectures based on printed electronics rather than silicon chips. "Additive manufacturing makes it possible to produce in small quantities with a small printer at favorable conditions because you are not dependent on large expensive production processes of silicon technology", Tahoori describes the potential. In addition, sensors equipped with printed electronics and implemented directly in the respective product can integrate more components, process information better and visualize it for users.

New type of calculations as a challenge

As simple as the implementation seems at first, however, it is not then. Additive manufacturing in its current form is not operational for the production of such minicomputers. "There are approaches to create sensors using additive manufacturing, but these processes are too slow for large volumes," Tahoori says, explaining the problem. "There are more than 100 billion transistors in silicon-based chips, compared to a maximum of 100 to 1000 components in printed electronics. In addition, there is the inaccuracy of manufacturing. If you print two transistors, for example, the probability that they will end up exactly the same is very low," Tahoori continues.

The big challenge, and thus the fundamental research question of PRICOM, is therefore how to perform accurate, reliable and energy-efficient classification calculations to meet the requirements of the project within the constraints of additive printing production. Simply put, the researchers plan to use a mix of analog and digital computation to do this. "Digital computation has been common in chip manufacturing. But because we have so few transistors and components in additive manufacturing, we can't get around analog computation because it works better and is more stable. On the other hand, it is also imprecise and very sensitive to fluctuations. With the mixed signal, meaning the use of both methods, we hope to find an optimal solution", explains Prof. Tahoori.

Analog and digital computing

Analog computing is based on solving mathematical problems by observing physical models with analog laws. The calculation is carried out with the aid of continuous mechanical or electrical processes and any intermediate values. The difference to digital computing lies in the distribution of values. Digital calculators, on the other hand, only work with certain discrete numbers, zero and one.

Bringing the vision to life

The researchers have already been able to successfully print, implement, and measure the first components in recent years. "At KIT, we have good experience in the field of additive manufacturing. Added to this is our enormous expertise for computer science methods and electrical engineering. This combination of printed electronics and informatics is rare. We are positioned very well in machine learning and artificial intelligence. The mix of these different areas is crucial to our approach and we are on a very good path," describes Tahoori. Currently, the team is working on the stability of printed chips. Tahoori is optimistic about the future: "In many important areas of life, such as the fast-moving consumer goods (FMCG) market or personalized medicine, the added value of computer technology has not yet been tapped, mainly because of the high production costs for rigid silicon technologies. Yet these applications account for an enormously high market volume and thus offer great potential for smart technologies. I am very optimistic that we will be able to generate presentable application projects with PRICOM and thus better calculate certain aspects of our lives. With the goal of extending semiconductor chips and already available printed electronics with highly customizable, very low-cost, integrated electronics with computing capacity. Moving away from the desert to a better quality of life."

Further links

Images f.l.t.r.: Shawn H 58 empel / Shutterstock | Kira Heid / KIT