Fiber-reinforced plastics (FRP) are a relatively young group of materials - composites consisting of technical fibers, such as glass, carbon or aramid, embedded in a polymer matrix. Combining fibers and matrix agent, the fiber composite achieves robust properties with high specific stiffness and strength through mutual interaction and adhesive and cohersive forces.

The material properties of the fiber-plastic composite can be adjusted by fiber angle, fiber volume fraction and layer sequence, among others.

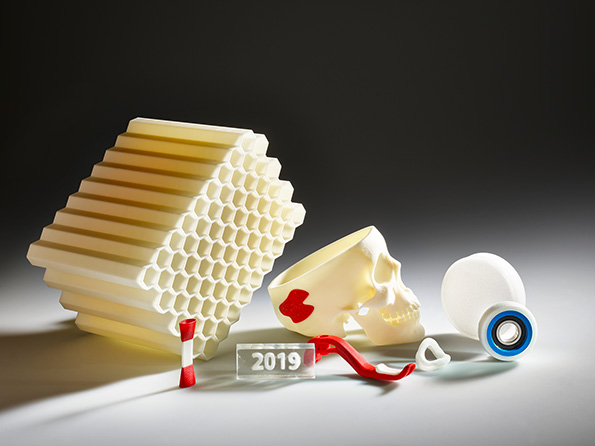

The areas of application for fiber-reinforced plastics are steadily increasing, also due to the development of new additive production methods. In many cases, they have already replaced the metallic materials traditionally used. In the following, we will introduce two common fiber composites with their specific areas of application.

Composite material with glass fibers

Glass fiber-reinforced plastic, or GFRP, is the most commonly used fiber composite reinforcing material. The basic advantage of GFRP is low cost, lightweight, high stability and corrosion resistance. GFRP is non-absorbent, easy to wash off and disinfect.

GFRP is mainly used in the automotive, aerospace and naval industries where it is commonly found in body parts or structural components. GFRP is also suitable for use in wind turbines or bridges. Furthemore, the material’s high versatility allows it to be used as a container in plant engineering and pipe power construction. GRFP is also interesting for the electrical industry because of its good insulation properties. In everyday life, GRFP is used in clothing and sanitary units, such as bathroom sinks or shower trays. In the leisure sector, you can find GRFP in caravan and motor home construction or GRFP profiles as tent poles or sail battens.

Composite material with carbon fibers

Carbon-fiber-reinforced plastics, or CFRP, are tried and tested for components with high thermal and mechanical requirements. CFRP components demonstrate tensile and flexural strength, impact resistance and the ability to sustain loads. They are also lighter than all-metal parts and resistant to very high temperatures. For this reason, CFRP is used especially for heavy-duty, very rigid components.

CFRP components are expensive to manufacture compared with commercially used metal components of the same load-bearing capacity. They are therefore used particularly where stable lightweight structures are required and where low mass combined with high stiffness is accepted for increased costs, i.e. mostly for special applications.

The use of CFRP is widespread in aerospace engineering, yacht building, medical technology and high-quality automotive parts. CFRP is also used in boat building, for example for rotor blades, or in the sporting goods industry for professional sports equipment, such as golf clubs, bicycle components or ski equipment, due to its good material properties.

Picture: ARBURG GmbH + Co KG