- Information

- Climate, Environment & Health

- Materials

MEASURING THE COLD

Researchers would love to put everything on the scales. Then they could find out without detours what a neutrino weighs. And they would know exactly how many grams of helium flow through a pipeline per second.

Professor Steffen Grohmann is primarily interested in the helium problem. He is an engineer for refrigeration and cryogenics and thus, an expert in generating very low temperatures. The scientist works at Institute of Technical Thermodynamics and Refrigeration as well as Institute of Technical Physics. "Unfortunately, no commercial sensors exist for flow measurement in cryogenics," Grohmann explains. Yet there would definitely be a great need for such measuring devices. After all, cryogenics is needed wherever superconductors are in use, for example for the operation of particle accelerators and in future fusion reactors. Hydrogen technology and the extraction of oxygen and noble gases from the air are also based on cryogenics.

Scientists also rely on cryogenics for the KATRIN project, a huge facility to determine the mass of the neutrino. The neutrino mass plays an important role in cosmology, as the easily underestimated particles help shape the evolution of the universe - from the Big Bang to the present day. Knowing the exact properties of neutrinos could also help physicists unravel how other elementary particles got their mass. Because neutrinos fly through matter virtually unimpeded and without leaving a trace, their mass must be measured with a very special and sensitive balance.

Neutrinos are produced, for example, during the decay of tritium, also known as superheavy hydrogen. In the KATRIN experiment, the tritium cools to a temperature of 30 Kelvin, which corresponds to about minus 243 degrees Celsius. Low-temperature technology is also used in other areas of the experiment: The electrons produced during tritium decay are transported through the 70-meter-long experiment with the help of superconducting electromagnets. To cool these superconductors, cryogenic engineers use liquid helium cooled down to just 4 Kelvin.

Many of the flow sensors available on the market today are intended for ambient temperature applications. As with all other measuring devices, strict regulations apply to measurement uncertainty: the manufacturer in accredited laboratories must calibrate the devices. In the case of cryotechnical applications, however, this is not practical because the entire cryotechnical infrastructure would have to be set up and operate in the calibration laboratory, which would involve enormous costs.

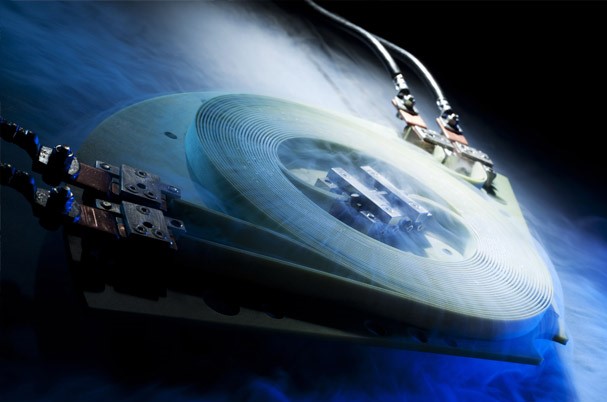

"We have developed a completely new measurement principle at KIT. This makes it possible to build sensors that can calibrate themselves during operation. Such sensors are also capable of learning because the measurement uncertainty decreases with each calibration performed," explains engineer Grohmann. The principle is based on two independent and physically exact equations that describe how mass flow can be calculated from the measured variables temperature and heat output of a heat exchanger. To determine the actual mass flow, the scatter of the results of both equations is minimized. One advantage of the method is that the size of the systematic errors does not matter. "I don't have to measure temperatures and heat output accurately at all. A consistently wrong measurement still leads to correct results," says Grohmann. Indeed, through clever evaluation, it is possible to eliminate the systematic errors and thus keep the measurement uncertainty of the mass flow below one percent.

Grohmann applied for a patent for this idea, which is revolutionary for measurement technology, in 2011 and submitted it to KIT NEULAND Innovation Competition one year later. The resulting project "Development of a flow sensor for cryotechnical applications" won first place in NEULAND Special Prize for Technology Transfer Projects in 2014. Supported by KIT Innovation Management, Grohmann, a cryotechnologist, found a suitable industrial partner for product development: Since 2013, the Swiss company WEKA AG has been a partner in a two-year technology transfer project, financially supported by KIT Innovation Fund. "We would not have been able to handle the complex development of the electronics on our own. A technology transfer project is therefore ideal, especially for us as a medium-sized company," says Michael Boersch, project manager for WEKA AG. The company specializes in the production of valves and measuring devices for cryotechnical applications. "The sensor, which is being developed jointly with KIT, perfectly complements our product portfolio," says Fridolin Holdener, senior manager at WEKA.

Meanwhile, development of a prototype of the sensor is underway. Since there are no commercial alternatives for flow sensors to use in cryogenics, the competitive situation is very advantageous. The project partners can concentrate fully on developing the technology. Potential customers for the sensor come primarily from cryogenic process engineering and science. However, the measuring principle works just as well for plants operated at ambient temperature. In the long term, the product could therefore complement classical measurement and control technology in process engineering.

The versatility of KIT is a great advantage in such an interdisciplinary project. In addition to Institute of Technical Thermodynamics and Refrigeration and Institute of Technical Physics, the Institute of Process Data Processing and Electronics is also involved. In the KATRIN experiment, the sensor will be used in the future to measure the tritium flux. This way, experiments in basic research can also generate product ideas and contribute to their implementation.

Perhaps in a few years, KIT scientists will not only know exactly how much gas flows through pipelines but also how heavy neutrinos are and what role they play in the small world of elementary particles and in the big, wide universe.

"It's exciting to see how the completely novel measurement principle we developed is implemented in a product."

Images: KIT