- Information

- Materials

THE GLOW OF THE FUTURE

The pictures in the newspaper move, the Minister of Magic waves at us friendly from the side - it looks familiar to "Harry Potter" readers. A television that can be rolled up like a roller blind - wasn't there a short sequence in the movie "Back to the Future"? To make such fantasy images a reality, screens would have to be very thin, flexible and printable. A technology that seems to be far away in the future. The founders of KIT start-up cynora bring science fiction into the present.

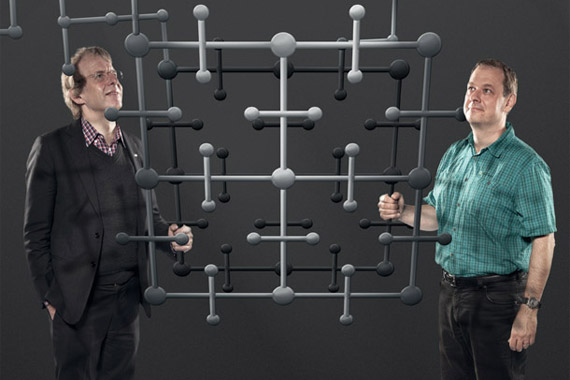

"You only come up with such an idea if you have no idea of the difficulties of technical implementation," says Tobias Grab, Ph.D., CEO of cynora GmbH. That is why he calls the idea of realizing high-tech print displays, which he and his co-founders had four years ago as Ph.D. students at KIT, a hallucination. The hallucination became a vision and finally the business model of cynora. Today, cynora's 26 employees are based in the high-tech incubator at KIT and at the growing site in Bruchsal near Karlsruhe. A portfolio of more than 70 patents is their carefully guarded treasure. "Face, brain, and hand" is how Tobias Grab describes the success concept of his company. Behind it are the different characters of the founding team.

Grab communicates the cynora vision as the "face" that is responsible for strategy, convinces investors, and represents the company on the international stage. Thomas Baumann, Ph.D., is the "brain" - he loves scientific work in its perfection and precision and focuses on the development of new substances in the laboratory and their patenting. Michael Baechle, as the "hand", ensures that visions and findings turn into commercial success and optimizes the processes of the young company.

In the meantime, their start-up is known far beyond the borders of the Karlsruhe region. In November 2013, it prevailed against 20 international start-ups and received the "Falling Walls Science Start-up of the year" award. The international "Falling Walls" conference in Berlin honors scientific start-ups whose innovations can break down walls and change the world.

The cynora researchers are developing substances that, when built into organic light-emitting diodes (OLEDs), could make everything glow and can be processed like printing ink to produce components. Screens as flat and flexible as a sheet of paper would be possible, as would printed lamps. Even the developers and managers at cynora could not have predicted the fact that the luminescent materials are so good. Luck, courage and optimism, but also scientific meticulousness and economic sobriety accompany cynora on its way from hallucination to excellent business model.

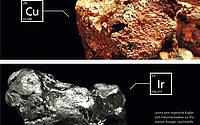

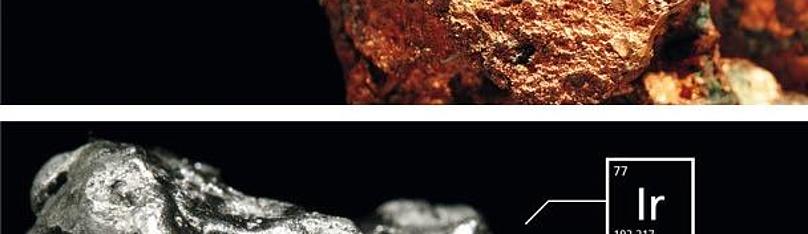

Today, smartphone manufacturers already rely on screens that consume very little energy thanks to OLEDs and display content brilliantly and in true colors. The disadvantage of OLED technology so far has been the high manufacturing costs. The phosphors currently used usually contain the extremely rare metal iridium. In addition, the semiconductor materials must be vapor-deposited onto a carrier substrate in a complex and thus, expensive process under high vacuum. "Manufacturers need innovation," says Tobias Grab. The market for screens and light sources is huge, and it is growing. Whoever manages to make OLED technology cheaper first will have won. All the major chemical and electronics companies are therefore intensively researching and developing suitable technologies.

The chemists at cynora are producing phosphors that contain copper instead of iridium, thus laying the foundation for a technological revolution. Compared to iridium, copper occurs much more frequently on earth and is therefore ideally suited for a mass market. Moreover, there is another advantage: The luminescent substances made from organic copper complexes can be processed in liquid form and therefore applied to a substrate like printing ink. This makes the luminescent substances suitable for the cost-effective production of large-area screens, such as those needed for television sets. Even paper-thin and flexible substrates would print in this way. They could be used as individually recordable window displays, advertising spaces or on intelligent product packaging.

Will one of the substances developed by cynora be used for printing and prevail on the world market? Or will one of the large corporations win the race? Thomas Baumann is optimistic: "The speed and courage of a small team gives us a real chance of prevailing against the power of the big companies."

"cynora has developed completely new classes of materials. The next goal is to bring these substances into commercial products and thus enable new applications."

Further Links

Images: KIT