VR Teleoperation - How Autonomous Robots Learn from Humans

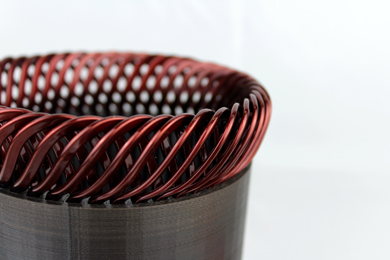

Industrial gripping of known items with defined pick and place positions has been state of the art for several years. Current developments use artificial neural networks for flexible gripping of objects with a-priori unknown pick and place positions, as it is necessary for example in order picking. For a correct classification of objects, i.e. the ability of the robot to recognize if the object to be gripped is the correct item, many images of an object as well as elaborate labeling are needed. If a new item is in the robot's gripping spectrum, this can lead to errors during picking or to a process interruption.

This is exactly where the VR teleoperation system comes in: In case of an unexpected case, the robot can request the help of a human VR teleoperator. During teleoperation, learning data is generated that can be taught to the system without interrupting the current operation, so that the system can independently grab the new item in the future.