- Energy

- Climate, Environment & Health

H2Mare

Alternatives to gray hydrogen are needed to meet Germany's growing demand for hydrogen while meeting climate targets. "One climate-friendly alternative is the production of green hydrogen by electrolysis. For this, we need renewable electricity. We do have wind and sun on land, but not for long periods of time at high intensity, so the number of full-load hours is limited at about 1,000 for photovoltaics and 2,000 to 2,500 for wind. On the high seas, on the other hand, conditions are better for generating electricity from wind power. With up to 15 megawatts of power per turbine and about 4,000 to 5,000 full-load hours, offshore wind turbines generate more electricity more regularly than the smaller onshore wind turbines," explains Prof. Dr. Roland Dittmeyer, head of the Institute of Microprocess Engineering (IMVT).

Offshore wind farms have enormous energy potential. The project partners in H2Mare want to make use of this. The idea is to produce hydrogen directly at sea. "Transporting the electricity from large, far-out offshore wind farms to shore to run electrolysis for hydrogen production there has disadvantages: firstly, economically, because you need a lot of expensive power lines; secondly, with regard to environmental compatibility, because these cable systems represent a major intervention in the maritime environment; and thirdly, technically, because feeding large amounts of electricity into the offshore grid requires a great deal of technical effort. So why not produce hydrogen directly where the renewable energy is generated," elaborates Dittmeyer. To make this possible, the researchers want to couple water electrolysers directly to offshore wind turbines that are not connected to the grid. Two concepts are being pursued: One integrates the electrolyzer directly into the wind turbine by attaching a small platform at the base of each turbine, on which up to three compact 5 MW water electrolyzers and a seawater desalination plant will be placed. The other considers the production of hydrogen downstream products such as methane, methanol, liquid hydrocarbons and ammonia on a central offshore power-to-X platform integrated into the wind farm. In addition to assessing the technical and economic feasibility and environmental compatibility of offshore production of power-to-X products, including the logistics required for this, the project partners want to develop a concept for an offshore research platform that could be built as a follow-up to the project in order to specifically further develop particularly promising PtX processes for offshore use. To this end, they are also planning a floating offshore test platform on which initial experience with the dynamic operation of a power-to-X plant in the real environment will be gathered toward the end of the project. "This platform will be equipped with a complete power-to-X process chain and the necessary peripherals for autonomous operation. Sounds simple, but it certainly brings challenges. For one thing, the equipment must be protected against salt water, even in bad weather. Secondly, a higher-level control system for the entire plant must be developed, which also includes a seawater desalination stage and a stage for extracting CO2 from the ambient air. The overall plant must be operated with variable output over time, as would be the case if it were directly coupled to a real wind turbine," says Dittmeyer, describing the challenges in the project.

Related links:

- Project video: https://www.youtube.com/watch?v=aQMH7l8TenQ

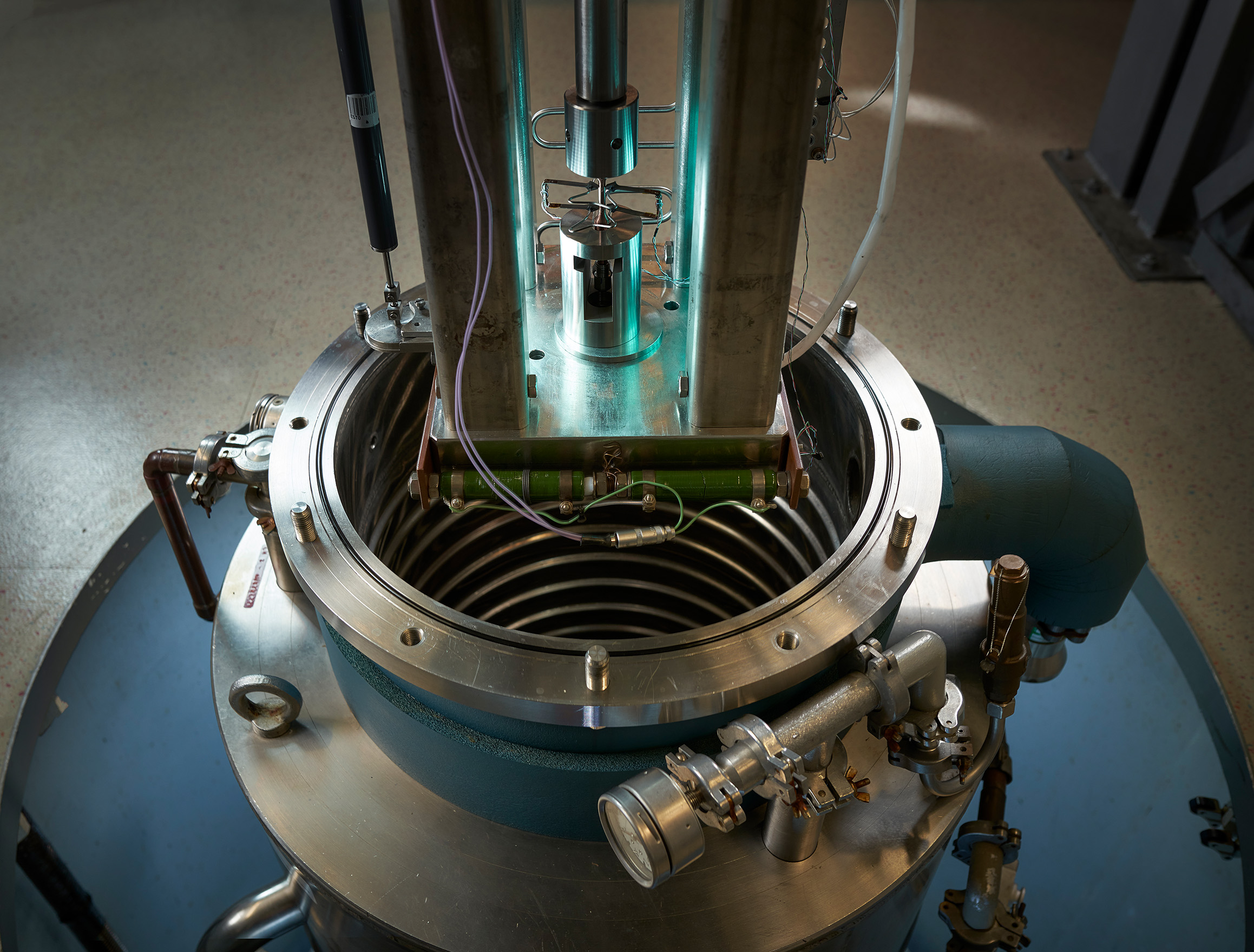

Image: INNOVEN GmbH