- Energy

- Climate, Environment & Health

H2Giga

There are already some companies that manufacture the electrolysers needed for the production of green hydrogen in small series. Although Germany's exact future demand for hydrogen is still unclear, it should be clear that it will be several million tons per year and that the required number of electrolyzers will require industrialization of production. "In the future, we will need large capacities of efficient, robust and powerful electrolyzers and thus companies that can manufacture them on a large scale," explains Dr. Philipp Röse, group leader of electrocatalysis at the Institute for Applied Materials - Electrochemical Technologies (IAM-ET).

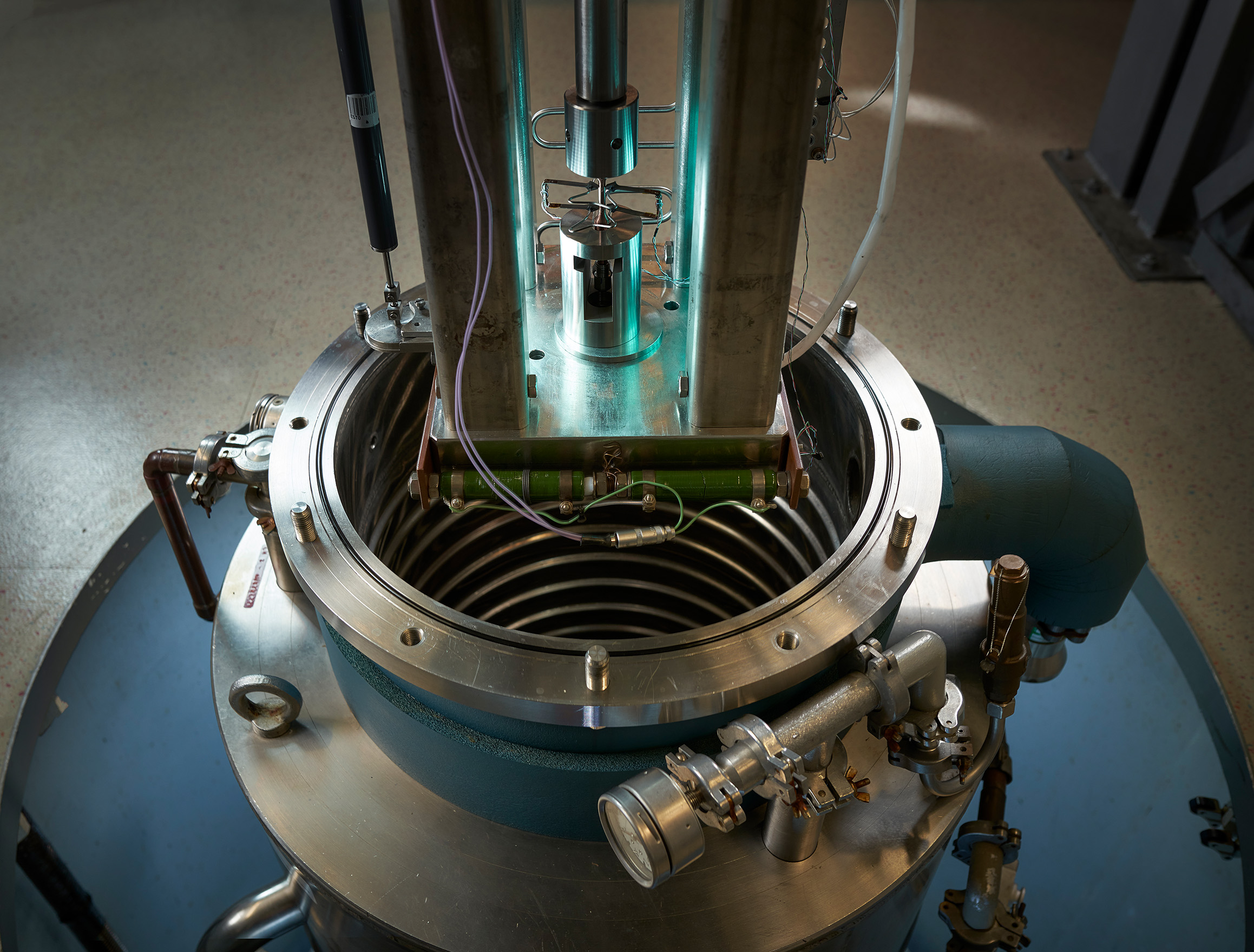

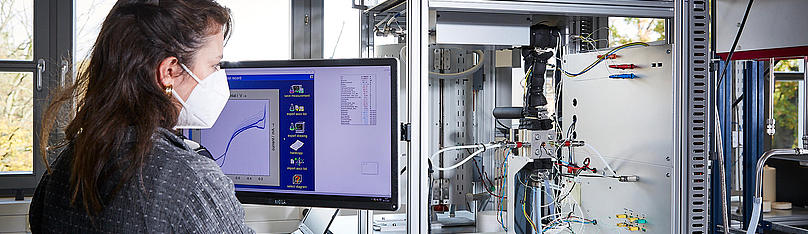

The automated production of water electrolysers on a gigawatt scale is being investigated by industry and research in the H2Giga project. The research is open to all technologies. Together with established electrolyzer manufacturers, suppliers from various technology areas and other research institutions, Röse is investigating proton exchange membrane electrolysis (PEM) in the StacIE project (Scale Up PEM EL Industrialization Stack). His colleague Dr.-Ing. André Weber, group leader Batteries, Fuel Cells and Electrolysis at IAM-ET, is additionally investigating high-temperature electrolysis (HTEL) in addition to PEM electrolysis in the HTEL Stacks project. "We look at the electrochemical processes in the projects and focus on the electrochemically active components. From the catalyst to the electrodes and cell to the interconnection of these in large cell stacks, we characterize the components of the electrolyzers experimentally and by means of digital models in order to identify necessary changes for series production of large-scale electrolysis stacks," says Weber, describing KIT's scope of work in the project. Röse specifies: "We are primarily concerned with cell characterization, i.e., we look at different cell types on a small scale, try to understand them in detail, evaluate them, and, of course, identify potential problems at an early stage. This could be aging or insufficient performance, for example." The research always takes place in close exchange with industry. "We can then mirror the results back to the companies, which can use this as a basis for targeted optimization and transfer the whole thing to the large scale," says Weber.

Images: Magali Hauser / KIT